Are you always looking for the most efficient ways to finish your fabric-cutting projects?

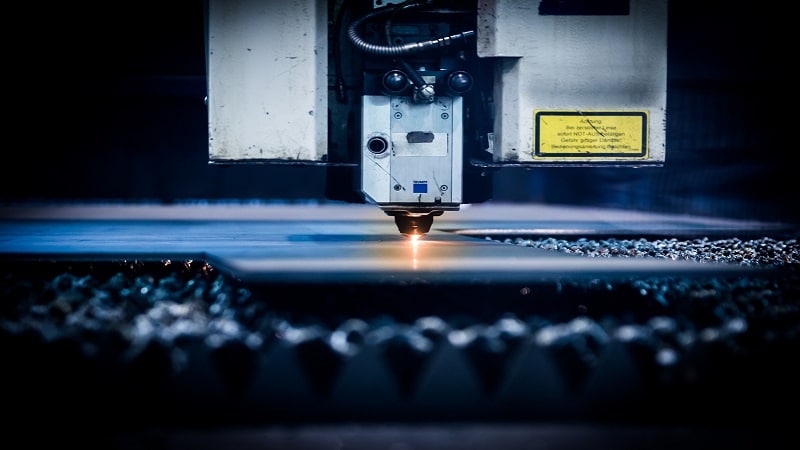

If so, then you've come to the right place. In this blog post, we are going to explore how new technologies, such as laser fabric cutter, have revolutionized cutting efficiency and changed the way people approach traditional methods of working with fabrics. From small projects at home to large-scale manufacturing operations in factories, lasers open up many possibilities that can drastically decrease completion times while decreasing errors due to human elements.

The innovation of the laser fabric cutter has significantly enhanced efficiency in various industries. To explore the latest advancements in laser-cutting technology, consider reaching out to a reputable laser cutting machine supplier for expert guidance and top-notch equipment.

Read on as we examine the incredible advances made by laser fabric cutters and why they remain one of the best investments anyone can make when pursuing their own fabrication or clothing-making endeavors!

Here Are Seven Ways How The Innovation Of Laser Fabric Cutter Enhanced Efficiency:

1. Reduced production time

The innovation of the laser fabric cutter has revolutionized the entire manufacturing process of the textile industry. This new technology has made cutting fabrics much quicker and more accurate. The laser fabric cutter precisely cuts through materials using a high-powered laser beam.

This reduces the need for manual cutting and improves the overall efficiency of the production process. Not only does it save time, but it also reduces waste and improves the quality of the finished products. Laser cutting has transformed traditional methods and created a more innovative, sustainable, and efficient way of fabric cutting. With this incredible technology, the future of the textile industry looks brighter than ever.

2. Enhanced precision and accuracy

The innovation of laser fabric cutters has brought a new era of immense precision and accuracy to the textile industry. These cutting-edge machines have transformed how fabrics are cut, ensuring that every piece is perfectly shaped and sized. With laser technology, fabric manufacturers can now produce high-quality products faster and more efficiently.

Not only does this advancement help increase productivity, but it also helps to reduce waste and costs associated with manual fabric cutting. Improved efficiency in fabric production is essential in today's fast-paced world, and laser fabric cutters have undoubtedly raised the bar in achieving this objective. The precision and accuracy of these machines have revolutionized the fabric industry, leading to increased demand for these cutting-edge tools.

3. Increased production capacity

The innovation of the laser fabric cutter has been a game-changer for the apparel industry, enhancing efficiency like never before. Laser cutting has its own benefits in the textile industry. With increased production capacity, manufacturers can create more pieces in less time, reducing lead times and allowing for faster turnarounds.

This technology also allows for precise cuts and eliminates the need for manual labor, reducing errors and lowering costs. The result is an overall increase in productivity and profitability for businesses that adopt this cutting-edge tool. As we continue to see advancements in laser technology and automation, the possibilities for increased efficiency and innovation in the textile industry are endless.

4. Improved consistency and quality

With the innovation of laser fabric cutters, the world of textile and apparel manufacturing has been revolutionized to a great extent. The most significant advantage of laser fabric cutting is improved consistency and quality. The precision of the laser beam ensures that each cut is accurate and clean, resulting in garments that are better fitting and more aesthetically pleasing.

This technology allows fabrics to be cut much faster than traditional methods and with minimal waste. It also eliminates the need for physical cutting tools like knives and scissors, simplifying the entire process and reducing the risk of accidental workplace injuries. This has significantly enhanced efficiency, allowing textile manufacturers to produce high-quality products with incredible speed and accuracy.

5. Reduced material waste

In today's world, businesses are constantly looking for ways to increase their efficiency and reduce their environmental impact. One innovative solution that has gained popularity in recent years is the laser fabric cutter. Manufacturers can use this technology to reduce their material waste and optimize their production process.

The laser fabric cutter can help companies save time, money, and resources by accurately cutting fabric to precise dimensions with minimal error. Moreover, the precision of this cutting technique yields high-quality results, which can improve product quality and customer satisfaction. Overall, the innovation of the laser fabric cutter has enhanced the textile industry's efficiency, sustainability, and profitability.

6. Expanded design capabilities

Innovation in any industry has led to some unexpected yet profound results. The laser fabric cutter is one such innovation that has had a transformative effect on the textile industry. Laser-cutting technology has dramatically expanded design capabilities in this field, and the results have been astounding.

With laser technology's precision and accuracy, designers can easily create intricate and detailed designs. This exceptional innovation has significantly enhanced efficiency, allowing for more intricate and precise designs in a shorter time and at a lower cost. Ultimately, the advent of the laser fabric cutter has revolutionized the textile industry, and it's exciting to anticipate what the future holds for this transformative technology.

7. Improved overall production efficiency

Every industry strives to enhance productivity and efficiency in today's fast-paced world. One key innovation that has revolutionized the textile industry is the Laser Fabric Cutter. W

ith its precision and speed, the laser cutter has automated the process of fabric cutting, minimizing material wastage and maximizing yield. This technology has enabled manufacturers to tailor their production processes with unmatched speed and accuracy to customer needs. However, you must know why laser cutting machines are the best solution.

The accuracy of the laser cutter has significantly reduced the errors and inconsistencies that come with manual processes, improving overall production quality and resulting in higher customer satisfaction. The laser cutter has undoubtedly proven its worth in the textile industry in terms of efficiency and productivity.

Conclusion

Innovation is a powerful driver of economic stability, and the development of new methods has always been essential for fabric-cutting industries. To this end, the emergence of the Laser Fabric Cutter as an effective tool has revolutionized the industry, providing efficient and precise cuts with a fraction of the effort.

This technology can benefit any business looking to reduce time spent cutting fabric and avoid costly material wastage. Ultimately, this means more significant savings and higher business profits, so start using this innovative solution today!