Looking for a reliable CO2 laser head assembly factory? Look no further than our team here at the sourcing division of ecommerce company, Global Sources.

We specialize in helping businesses find the best CO2 laser head assembly factories worldwide, and we can tell you everything you need to know about this particular factory.

What is the CO2 laser head assembly factory?

The CO2 laser head assembly factory is the most important part of your laser system. It is responsible for ensuring that the laser beam is properly focused and directed to the target area. If this part of your laser system is not functioning correctly, your machine will not be able to produce accurate results.

When choosing a CO2 laser head assembly factory, it is important to consider factors such as quality control, warranty coverage, and customer service. It is also important to make sure that the factory has experience manufacturing CO2 lasers.

History of the CO2 laser head assembly factory

The CO2 laser head assembly factory has been in operation for over 20 years and is one of the leading CO2 laser head assembly factories in the world. They are able to produce high-quality CO2 laser heads at a low cost, which makes them a popular choice for manufacturers around the world.

The main reason why CO2 laser heads are so popular is because they have a wide range of applications. They can be used in medical procedures, manufacturing, and many other industries. The CO2 laser head assembly factory is able to meet the needs of many customers thanks to their variety of products and their low cost.

One of the biggest challenges that the CO2 laser head assembly factory faces is keeping up with demand. They are always trying to develop new products that will appeal to customers and meet their needs. This means that they must be constantly innovating in order to stay ahead of the competition.

Facilities of the CO2 laser head assembly factory

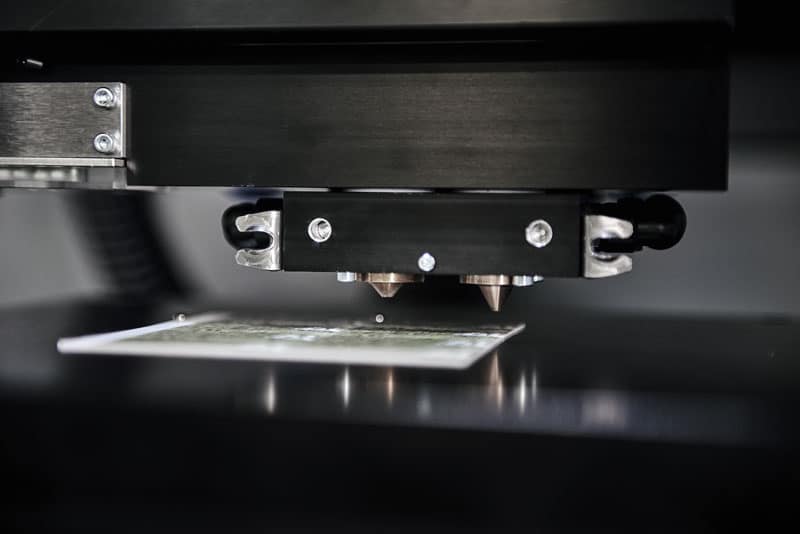

The CO2 laser head assembly factory is a highly specialized facility that manufactures the components needed to build carbon dioxide lasers. The factory is equipped with the latest in manufacturing technology and specializes in the production of precision parts and assemblies for carbon dioxide lasers.

To produce the components necessary for carbon dioxide lasers, the factory uses a variety of manufacturing processes, including machining, stamping, and welding. The factory also has a wide range of equipment available to it, including CNC machines, metalworking tools, and plasma cutters.

In order to manufacture its products accurately and with high quality standards, the CO2 laser head assembly factory employs a team of highly skilled specialists. These experts have years of experience in the fields of laser technology and manufacturing, and are able to provide customers with products that are accurate and reliable.

Products of the CO2 laser head assembly factory

In the CO2 laser head assembly factory, precision machining is used to create laser heads and modules. The factory uses advanced CNC machines that can produce parts with extremely high accuracy. This allows the factory to produce high-quality products that meet or exceed customer specifications.

The CO2 laser head assembly factory also offers a wide range of services, including engineering support, design and manufacturing services, and after-sales service. This means that customers can count on the factory to help them achieve their desired results.

The CO2 laser head assembly factory is a reliable resource for businesses looking for quality products and expert support. If you're interested in learning more about this facility, please get in touch with us today!

Tips to Consider When Contacting CO2 laser head assembly factory

When considering whether or not to contact a CO2 laser head assembly factory, there are a few tips to keep in mind. First, it is important to understand what exactly you need the factory to produce. Second, it is important to be realistic about the time and resources required for production. Finally, be sure to have a clear idea of pricing and timeline expectations before contacting the factory.

When first thinking about whether or not to contact a CO2 laser head assembly factory, it is important to think about what you need the factory to produce. Many times, businesses will require the assembly of custom CO2 laser heads. This means that the factory will need access to both the raw materials and fabrication capabilities required for production.

It is also important to remember that not all factories are capable of producing custom CO2 laser heads. In general, factories that produce standard CO2 laser heads are more likely to be able to provide services geared towards producing custom laser heads.

Once you have an idea of what you want the factory to produce, it is important to consider resource requirements. Often times, factories will require access to machinery and equipment necessary for production. This includes everything from CNC machines and machining centers, through welding and fabricating facilities.

Furthermore, many factories will require lead time in order for them complete your project – this means that you may needto factor in additional time when estimating timelines for production.

Conclusion

The CO2 laser head assembly factory is an important part of the manufacturing process for medical equipment. By producing quality parts that meet or exceed customer requirements, this factory ensures that patients receive the best possible care.

With years of experience in the industry, the team at this factory knows how to get your products to market quickly and efficiently. Contact us today if you have any questions about our products or services – we would be happy to help!